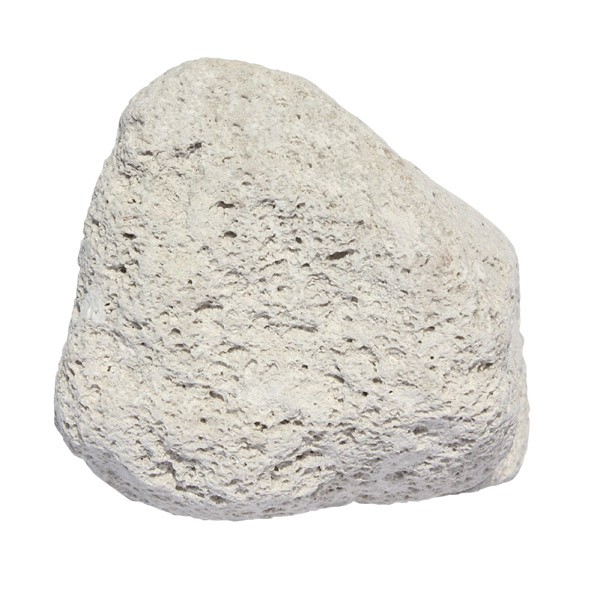

Pumice Stone

Pumice

Pumice /ˈpʌmɨs/, called pumicite in its powdered or dust form, is a volcanic rock that consists of highly vesicular rough textured volcanic glass, which may or may not contain crystals. It is typically light colored. Scoria is another vesicular volcanic rock that differs from pumice in having larger vesicles and thicker vesicle walls and being dark colored and denser.

Pumice is created when super-heated, highly pressurized rock is violently ejected from a volcano. The unusual foamy configuration of pumice happens because of simultaneous rapid cooling and rapid depressurization. The depressurization creates bubbles by lowering the solubility of gases (including water and CO2) that are dissolved in the lava, causing the gases to rapidly exsolve (like the bubbles of CO2 that appear when a carbonated drink is opened). The simultaneous cooling and depressurization freezes the bubbles in the matrix. Eruptions under water are rapidly cooled and the large volume of pumice created can be a shipping hazard for cargo ships.

Origins of Pumice

The word pumice is derived from the Latin word pumex, meaning foam.

Pozzolan (or pozzolana) is an Italian word, named from Pozzuoli, the place near Naples where pozzolan was first mined and used as cement, during Roman times.

Pumice is a textural rock formed from volcanic eruptions. Deep underground, molten rock incorporates water and other gases, and when the magma erupts from a vent, the gases flash off, leaving behind a frothy, vesicle-riven structure that quickly cools, solidifying the foamy structure. The magma has now transformed into an amorphous aluminum silicate, or pumice.

The unusual foamy configuration of pumice happens because of simultaneous rapid cooling and rapid de-pressurization. Pumice Stone commonly originated from Indonesia and Turkey.

Different sizes of Pumice Stones are available, such as 1-2 cm, 1-3 cm which known as small Pumice Stone. 2-3 cm, 2-4 cm which known as medium size Pumice Stone. And 3-5 cm, 5-7 cm which is known as Large size Pumice Stone.

The hardness of Pumice Stone in Mohr scale is 6. The melting temperature of Pumice Stone is 15000˚ C and pH value is 8 and the density is 2.313g/cm3.

Manufacturing and Finishing Processes using Pumice

Textile Softening: Known as stone-washing, pumice stones are tumbled with stiff fabrics or assembled garments (like denim) to soften the feel and age the appearance. Pumice stones are not only highly effective at giving fabric a natural worn-in look and feel, but pumice stones are long lasting and gentle on the expensive tumbling machinery. As for environmental friendliness…a natural pumice beats chemical and enzyme baths hands-down.

Pumice stone usage in stone wash

Stone washing is a textile manufacturing process used to give a newly manufactured cloth garment a worn-in (or worn-out) appearance. Stone-washing also helps to increase the softness and flexibility of otherwise stiff and rigid fabrics such as canvas and denim.

In stone-washing the worn-out look is given purposely. The fabric is washed along with pumice stones. The stones and denim are spun together in large industrial washing machines. The longer they are spun together lighter the color of the fabric with better contrasts would result. The time duration of this procedure is set beforehand so as to avoid the tear and wear of the fabric. Thereafter, the fabric undergoes various other processes of rinsing, softening and finally tumble-drying. These stone-washed fabrics are used for different purposes — garment making as well as for upholstery purpose.

The process uses large stones to roughen up the fabric being processed. The garments are placed in a large horizontal industrial clothes washer that is also filled with large stones. As the wash cylinder rotates, the cloth fibers are repeatedly pounded and beaten as the tumbling stones ride up the paddles inside the drum and fall back down onto the fabric.

A number of people and organizations have claimed to have invented stone-washing. According to Levi Strauss & Co., Donald Freeland, an employee of the Great Western Garment Company (later acquired by Levi's), invented "stone-washing" denim in the 1950s. Inventor Claude Blankiet has also been credited with having invented the technique in the 1970s. The jeans company Edwin claims to have invented the technique in the 1980s.

Object of Stone Washing:

1 To create or produce irregular fading or old looking affect on garments.

2 To remove dust, oil spot, impurities from the garments.

3 For soft felling to wear the garments i.e; to improve softness.

4 To achieve the buyer washing standard.

ZenStone Pumice produce and ship following calibers :

• 3-8 mm Pumice Stone double washed, three times tumbled

• 7-15 mm Pumice Stone double washed, three times tumbled

• 1-2 cm Pumice Stone double washed, three times tumbled

• 1-3 cm Pumice Stone double washed, three times tumbled

• 2-3 cm Pumice Stone double washed, three times tumbled

• 2-4 cm Pumice Stone double washed, three times tumbled

• 3-5 cm pumice stone double washed, three times tumbled

• 5-7 cm pumice stone double washed, three times tumbled

Chemical Analysis

Pumice stone’s typical chemical composition is:

| Silicon dioxide SiO2 | 80.42% |

| Aluminium oxide Al2O3 | 9.32% |

| Ferric oxide Fe2O3 | 1.03% |

| Calcium Oxide CaO | 1.46% |

| Magnesium Oxide MgO | 0.32% |

| Sulphur Trioxide SO3 | 0.03% |

| Potassium Oxide K2O | 2.30% |

| Sodium Oxide Νa2O | 2.20% |

| Calcification Loss | 2.71% |

| Indefinable content | 0.21% |

| 100.00% |